MIG Welding Gas Options: What to Consider for Optimal Results

Introduction

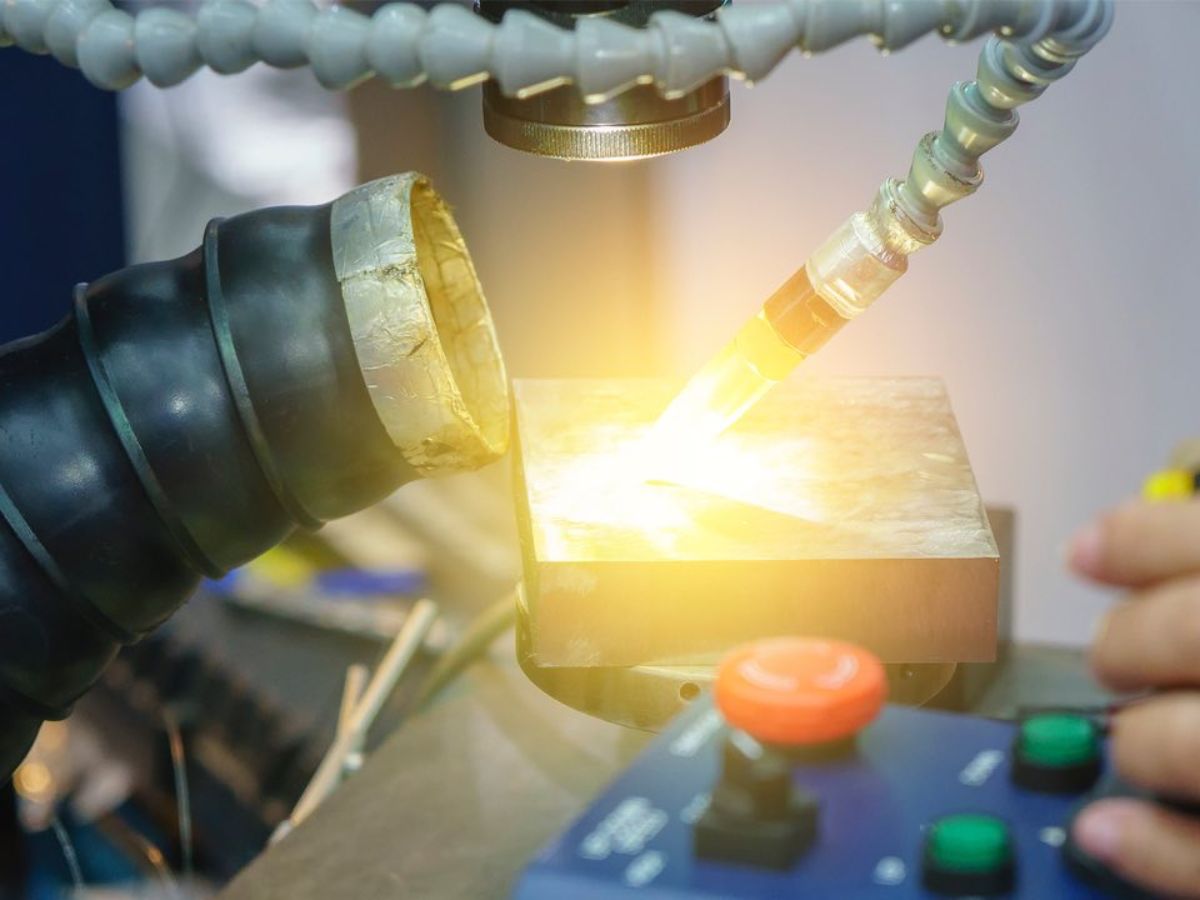

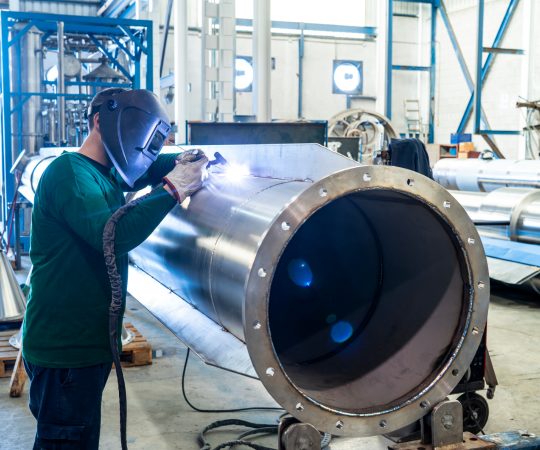

MIG welding, short for Metal Inert Gas welding, is a popular and versatile welding process utilized across various industries. The choice of welding gas plays a pivotal role in achieving optimal results, influencing everything from the quality of the weld to the safety of the welder. In this article, we will delve into the different gas options available for MIG welding and what factors you should consider when making your selection. Additionally, we'll explore common queries regarding welding safety, practices, and equipment to arm you with comprehensive knowledge.

MIG Welding Gas Options: What to Consider for Optimal Results

When it comes to MIG welding, the gas used can significantly affect the outcome of your project. The most commonly used gases include Argon, Carbon Dioxide (CO2), and a mixture of both. Each has its advantages and disadvantages depending on several factors such as material type, thickness, and desired characteristics of the finished weld.

Understanding MIG Welding Gases

What Are MIG Welding Gases?

MIG welding gases are essential components of the welding process that protect the molten metal from atmospheric contamination. By creating an inert or semi-inert environment around the weld pool, these gases help in preventing oxidation and other adverse reactions during the welding process.

Types of MIG Welding Gases

- Pure argon is often favored for aluminum and non-ferrous materials due to its inert properties.

- It produces a smooth arc with minimal spatter.

- CO2 is less expensive than argon but can lead to more spatter.

- It's often used for mild steel applications due to its ability to provide deeper penetration.

- A blend of argon and CO2 offers a balance between cost-effectiveness and performance.

- This mixture reduces spatter while maintaining good penetration levels.

Factors to Consider When Choosing MIG Welding Gas

Material Type

The type of metal you’re working on greatly influences your gas choice. For example:

- Aluminum: Typically requires pure argon or an argon/helium mix.

- Mild Steel: Often welded with CO2 or an argon/CO2 mixture.

- Stainless Steel: Generally benefits from an argon/CO2 mix or pure argon.

Weld Quality Requirements

If you're aiming for high-quality aesthetics with minimal spatter, opt for pure argon or mixed gases. If penetration is more critical than appearance, CO2 might be more suitable due to its deeper weld profile.

Thickness of Material

The thickness of the material also plays a significant role:

- Thinner materials may require gas mixtures that provide lower heat input.

- Thicker sections might benefit from CO2 due to its enhanced penetration capabilities.

Safety Concerns Related to Welding Fumes

Are welding fumes toxic? The short answer is yes; prolonged exposure can lead to serious health issues including respiratory problems. Understanding how different gases impact fumes is crucial in selecting your MIG welding approach:

- Use adequate ventilation systems whenever you’re working with carbon dioxide or any mixture containing it.

- Investing in high-quality personal protective equipment (PPE) like helmets and gloves can mitigate risks associated with toxic fumes.

Welding Equipment Essentials

Welding Machine Types

Choosing a reliable machine tailored for your specific needs can make all the difference in your project’s success:

- Transformer-based Welders: Suitable for heavy-duty work but may not be portable.

- Inverter Welders: Lightweight and versatile; ideal for both home use and professional environments.

Welding Wire Selection

Different wires can affect your overall results:

- Commonly used with shielding gases; ideal for clean surfaces.

- Allows for outdoor use without shielding gas; better for dirty surfaces but produces more smoke.

Protective Gear: Essential Safety Measures

Are Welding Gloves Heat Resistant?

Absolutely! Quality welding gloves are designed specifically to withstand high temperatures while providing dexterity necessary for detailed work. Look out for gloves made from leather or specialized synthetic materials offering both heat resistance and flexibility.

Are Welding Helmets Solar Powered?

Many modern helmets feature solar-powered options that charge while you're working—eliminating battery replacements while providing automatic darkening features when you strike an arc.

Preparing Your Workspace Safely

Before starting any welding project, ensure your workspace is prepared adequately:

Common Questions About MIG Welding Practices

1. What welding rod should I use?

Your choice depends on what material you're working with:

- For stainless steel: ER308L rods are common.

- For mild steel: ER70S-6 rods are widely used.

2. What welding gas should I use for aluminum?

Pure argon or an argon-helium mix typically provides excellent results when working with aluminum due to their inert qualities.

3. How does MIG welding work?

MIG welding operates by feeding a continuous wire electrode through a gun into a weld pool while simultaneously supplying shielding gas to protect against contaminants in the air during fusion processes.

Conclusion

In summary, choosing the right MIG welding gas involves carefully considering multiple factors such as material type, desired quality level, safety concerns related to fumes, and even economic considerations regarding cost-effectiveness versus performance outcomes. Whether you're engaged in professional projects or personal endeavors like DIY crafts at home, understanding these options will undoubtedly help you achieve optimal results in your work while ensuring safety remains paramount throughout each step of your process.

By understanding these essential aspects of MIG welding gases—alongside proper protective measures—you'll be well-equipped not only to enhance your skills but also contribute positively within this rewarding field that continues seeing robust demand today!